Robotics

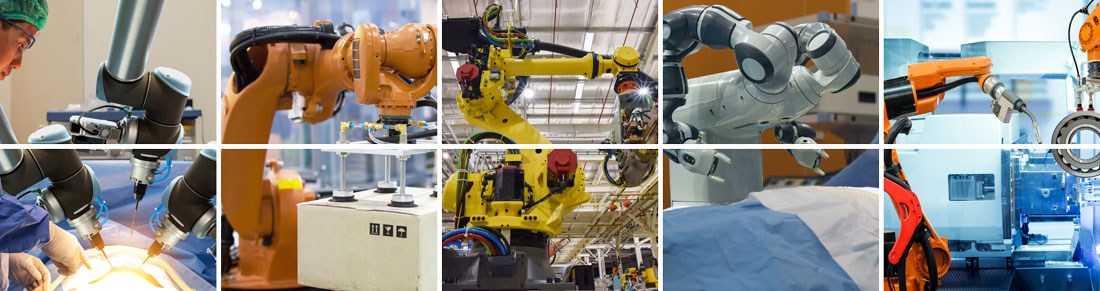

KEIKO is a specialist for special robotic solutions and uses the experience of many years as a system integrator of automation processes. As a robot system specialist, we create turnkey robot cells and take on the design, as well as the selection and procurement of the components to be used. Keiko also has core competencies in programming, motion simulation and commissioning the robot, as well as the system control and its user interface. Based on the robots of all well-known brands, we accelerate the processes and make the robot-supported workplaces safer. (Install link to AIRSKIN) Regardless of whether automated pick and place, packaging, welding or gluing, with the automation solutions from KEIKO and its experts you are equipped for Industry 4.0.

VR visualizations already in the development phase give you the feeling of standing in the middle of your new industrial plant. This saves time and helps to assess faults in the construction realistically already in the planning stage.

We are your expert for system integration – be it for a single production cell or a complete production plant. In our technology centre, we set up test systems, which can be take over and scaled up for series operation after successful pre-series processes.

Keiko plans and designs turnkey robot system solutions or linked robot lines for a variety of handling or machining tasks.

Anwendungsgebiete:

- Move – linear / rotating

- Gripping, storing, positioning

- Pivoting / rotating

- Pick & Place

- Mounting

- Palletizing

- Order

- Separating / combining

- Connect

- Removal from plastic injection moulding machines

- Feeding insert parts into injection moulds of plastic injection moulding machines

- Loading of machines

- packaging

- Laboratory analysis / tests

- Quality control

- Drilling / tapping / screwing

- Gluing

- Welding

- Polishing