Measure and Test

At Keiko, the coordination of material requirements and component tests begins in parallel with the specification. To ensure that our corporate goal of “zero-defect production” is not left to chance, all productions are subject to quality management coordinated with the customer.

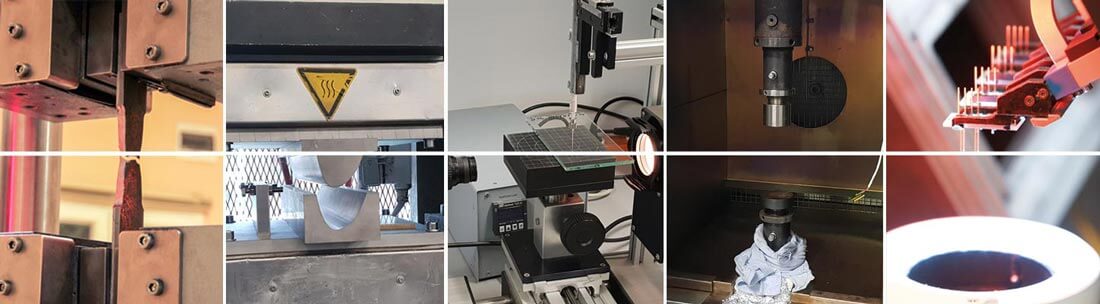

In addition to carrying out standardized mechanical and electronic tests, we develop product-specific test systems and develop simulation structures based on customer requirements. Furthermore, the testing of electrical components, environmental tests, temperature, vibration, shock, humidity, etc. as well as tests of EMC – electromagnetic compatibility are carried out.

Quality Assurance at Keiko

Within our mechanical test group we can offer the following mechanical properties of metals, ceramics, plastics and composite materials using calibrated measuring equipment and applying generally applicable standards (DIN, ASTM, EN, ISO, …). Together with our partners as well as well-known test institutes, universities and research institutions, we ensure that the desired requirements are met.

- Component testing

- Construction of product test benches and test facilities

- Measurement analysis and test reports

- Climate cabinet simulation

- Optical and mechanical testing